Environment & Filter Technology

Which system or machine you choose, we have the right filtering (filter system) for you.

COPPER-FEINSTFILTER

For copper-contaminated waste water from brushing machines. This fully automatic flood filter system allows a virtually 100% circulation of the water. As a rule, the addition of evaporation and procrastination losses due to fresh water is sufficient. The supplement is automatic. Kieselgur is used as a filter aid. The filter fineness is 0.5 microns. The residual Cu content of the circulating water is less than 1 ppm. The “Puromat” is adapted to the WESERO UNIVERSAL series and can be added to it without claiming additional space. However, the puromat inundate filter can also be used in other brands. A separate installation is also possible.

Applications:

Medium to large volume flows, with medium to severe co

ntamination of the liquid.

Applications:

Oil, water, emulsions (conditional), electroplating baths, washing solutions.

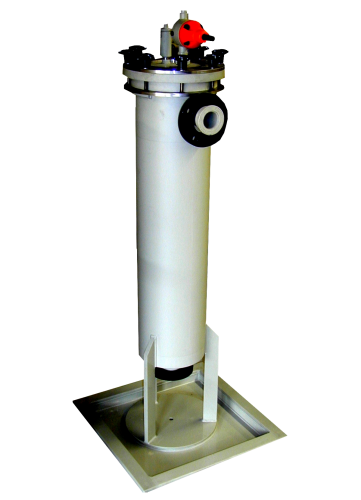

SANDFILTER

The system is used for the cleaning of circulating water from press plate cleaning machines. It consists of two water reservoirs, a dirty water pump, a sand filter, a machine supply pump and an electro-pneumatic valve control for automatic filter operation. The water reservoirs are welded from plastic and arranged next to the filter column. The dirty water from the machine flows into the dirty water tank. Float switches are attached to the container to monitor the water supply. The switches in the center of the container control the fresh water valve as soon as the mirror drops below the switching level.

Applications:

Medium to large volume flows, with moderate to medium contamination of the liquid.

Applications:

Oil, emulsion (conditional), water, washing solutions, electroplating baths

Material:

Stainless steel, PP

GRAVEL FILTER

The system is used for the cleaning of circulating water from press plate cleaning machines. The liquid to be cleaned is fed from above into the backwashable gravel-bag filter. The contaminated liquid penetrates through the gravel or sand layer. The impurities remain in the gravel/sand layer and are deposited there. The filtrate passes through the filter.

Due to the deposits of the impurities, the pressure in front of the filter increases. If a defined maximum pressure is reached, this is signaled by a message. The filter is now on “Backwash” to switch. For this time, the bag filter is switched. This allows the filter unit to run continuously in full current without the need for additional containers.

Applications:

Small to medium volume flows with medium to heavy contamination of the liquid.Con

ti operation

Applications:

Water, washing solutions, electroplating baths

Filter elements:

gravel, sand

Material:

Stainless steel, PP

CANDLE FILTER

The contaminated liquid is discharged from below under pressure into the candle filter. The liquid penetrates through the filter candles, with the impurities on the surface of the candle being retained. The pure medium comes out of the filter at the top. If a defined filter pressure is reached, the filter candles should be changed.

BAG FILTER

The liquid to be cleaned is discharged from above into the bag filter. The liquid penetrates through the filter bag in the bag filter. The impurities remain in the filter bag. As a result of the retained particles, the pressure in front of the filter increases. If a defined filter pressure is reached, the filter bag should be changed.

Applications:

Small to medium volume flows with medium to heavy contamination of the liquid.

Applications:

Oil, emulsion, water, washing solutions, electroplating baths

Material:

Stainless steel, steel, PP