Precision grinding machines

Individually designed according to your needs.

Grinding machine in different designs for grinding rubber webs, floor coverings, textiles, seals, conveyor belts, carbon plates, timing belts, drive belts and special applications.

Timing belt and drive belt grinding machines for grinding timing belts with widths of approx. 1000 mm which are then cut.

The WESERO Multi V Full Slab Grinder is equipped with a diamond-coated profiled grinding roller. The machine is used to profile Multi V Full Slabs.

Easy accessibility thanks to pneumatically hinged top. No adjustment of the grinding gap. Seams of goods webs can therefore simply pass through the machine without touching the grinding.

Track grinding machine in different design for grinding rubber webs, floor coverings, textiles, seals, conveyor belts and special applications.

What you should know about grinding systems...

Precision grinding machines for calibration to specified thickness.

Roughening to improve adhesive adhesion.

Production of decorative surfaces for webs or sheets made of rubber, plastic, phenolic, melamine, glass fibre reinforced epoxy laminates, fabrics, artificial leather, non-woven fabrics, textiles.

...about precision plate grinding machines

Easy access through pneumatically hinged upper part. No adjustment of the grinding gap. Seams of fabric webs can therefore simply pass through the machine without grinding contact.

- Small dimensions

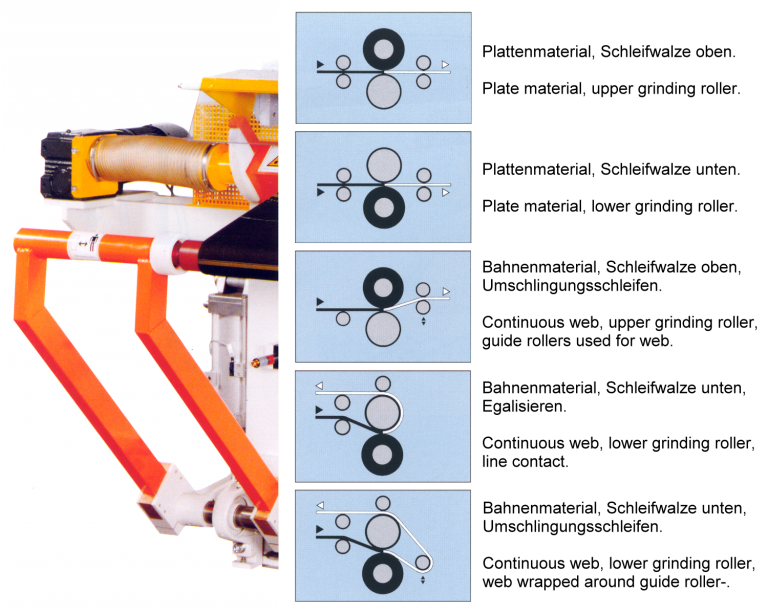

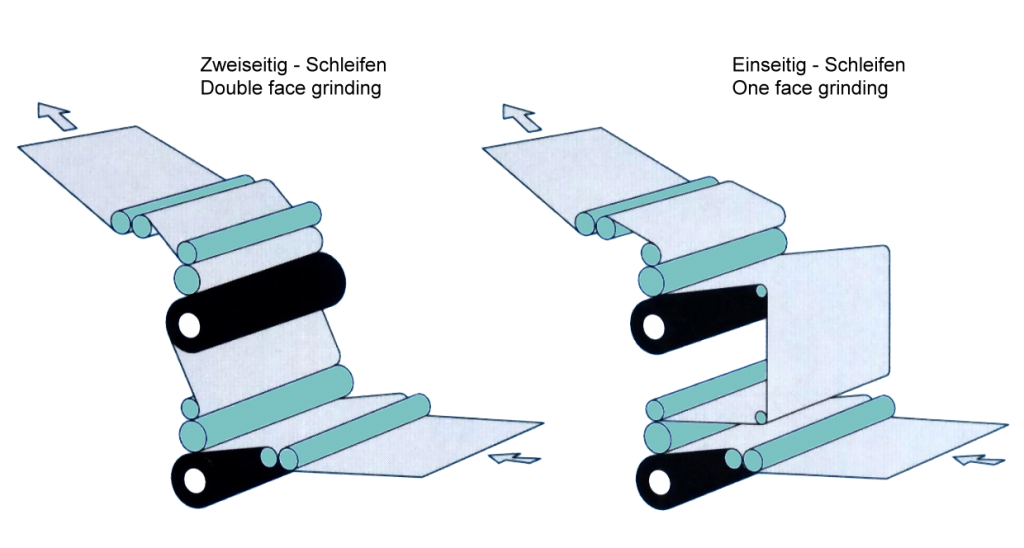

- Optional design with top or bottom sanding cylinder also allow simultaneous sanding of top and bottom side of material in automatic throughfeed systems

- Working widths up to 3000 mm possible

- Reversible conveyor drive

- Special device enables grinding of thin, flexible material sheets

- For thin and flexible webs the special wrap-around grinding is used. Here the web is guided around the sanding cylinder at an adjustable angle (wrap-around).

- Complete removal of the sanding dust by means of particularly streamlined air baffle plates in the machine in connection with a modern low-consumption and low-noise dust extraction system.

...over the grinding drum

- Use commercially available sandpaper dimensions.

- Depending on the purpose of processing, the type of abrasive, silicon carbide or aluminum oxide on paper, linen, fiber, etc., is selected. The grit sizes 16 to 60 are used for roughening work and 80 to 280 for fine grinding and decorative surfaces.

- Highest possible running smoothness due to electro-dynamically balanced sanding rollers.

- Specially developed quick-clamping and changing device for the abrasive paper by means of rotating, spring-loaded clamping heads.

- This automatically re-tensions the grinding paper.

- The grinding drum consists of a precision body, dynamically balanced, internally water-cooled and equipped with an oscillation device. Equipped on both sides with automatic sanding paper devices, which allow a quick paper change.

...about the drive system

Special WESERO design features: The transport drive with the long maintenance intervals by mechanically adjustable disco gear or thyristor controlled DC drive.

From WESERO – spur gear uniform drive of the transport and counter pressure rollers, over cardan shafts the oscillating movement of the grinding roller by gear motors. Eccentric head.

The WESERO cooling principle for the high-performance sanding roller by water.

Parallel thickness adjustment by motor or by smooth-running hand wheels on one side of the machine only. Control of the grinding gap via PLC, reading accuracy 1/10 mm digital.

The transport rollers are driven by the WESERO spur gear transfer box via cardan shafts and guarantee absolute synchronous operation.

All drives are accessible by swivelling the machine head.

Translated with www.DeepL.com/Translator (free version)

...and special machines

Toothed belt conveyor belts, hoses, web material.

...and special applications

Sanding and emery machine type TS/2-300 with 2 emery stations.

V-Belt Grinding Machine

The WESERO Multi V Full Slab Grinder is equipped with a diamond-coated profiled grinding roller. The machine is used to profile Multi V Full Slabs.

Technical Data:

| Thickness: | 1-5mm | |

| Material width: | max. 1080 mm | |

| Material length | 500-3000 mm | |

| Production speeds: | 3 – 6 m/min |

Timing belt grinding machine

Timing belt and drive belt grinding machines for grinding timing belts with widths of approx. 1000 mm which are then cut, designed for the automotive, automotive supply industry and machine manufacturers.

Technical Data:

(Parameters depend on machine type)

| Thickness: | 1 – 6,5mm | |

| Material width: | 1050mm max. | |

| Material length: | 130mm – 1500mm |

Plates grinding machine

Easy accessibility thanks to pneumatically hinged top. No adjustment of the grinding gap. Seams of goods webs can therefore simply pass through the machine without touching the grinding.

Technical Data:

(Parameters depend on machine type)

| Thickness: | bis 40mm | |

| Material width: | bis 1250mm | |

| Production speeds: | 4 – 24m/min |

Tracks grinding machine

Track grinding machine in different design for grinding rubber webs, floor coverings, textiles, seals, conveyor belts and special applications.

The machine has been specially developed for roughening/eleging web material in continuous operation.

The high weight, the stiffness of the machine frame, as well as the precise machining guarantee an almost vibration-free machine with very low vibration run of the grinding drum and a maximum of grinding accuracy.

Technical Data:

(Parameters depend on machine type)

| Working widths: | max. 2400mm | |

| Production speeds: | 0 – 60m/min |